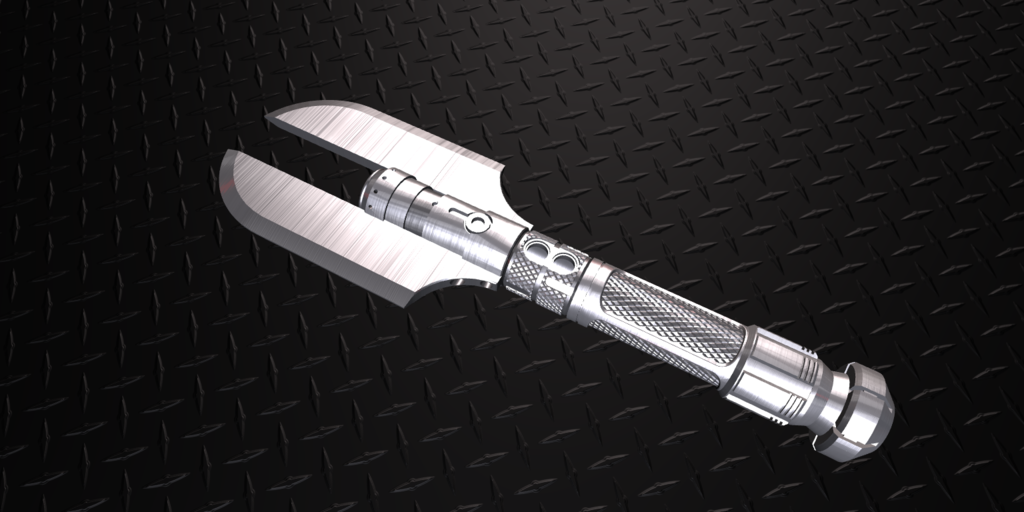

I have just received my ASP Juggernaut, all silver finish. yellow blade.

As part of the stretch goal reward, I received a silver spear extension. So far, the spear extension is the only part that I have seen others had received as well. Anyone received some other parts besides the spear extension?

Firstly, the parts arrived all assembled, except for the electronics. I ordered a warrior tier. So I had to disassemble it. The body and pommel came off easily. But for the life of me, I couldn't separate the switch section from the emitter. I tried using the hair dryer to heat the switch section so that it would expand a little for disassembly but it would budge at all.

That means I had install the switch with the emitter in place. Initially I thought of screwing the switch nut in place to secure the switch but since it's beyond what my fingers could reach, i had to settle putting in the switch without the nut. The battery holder seems a tiny fraction too small for the battery but i managed to force it in.

After putting in the LED module, I tried to screw in the retention screw but no matter how i tried i just couldn't screw it in. When I had a closer look at the hole, i noticed the LED module is right up against the wall of the emitter. That metal wall looks like 2mm thick at the most. There's just too little metal there to form any thread at all, and so the retention screw just wouldn't go in. To me, the LED retention screw is no big deal because with the blade plug or the blade in, the LED module is sandwiched between the blade/blade plug and the switch, so it's not going anywhere. But there's an ugly hole there. I think will stick a red button there, which the juggernaut lacks.

My biggest disappointment is the finish of the metal itself. I have a venom, standard finish. Brushed metal or polish kind of finish which i like. I also have a reborn, which is all silver and the finish is satin, which i absolutely hate. So when the ASP was announced and we get to choose the parts, I consciously wanted to avoid something which has satin finish.

In the saber builder, when the parts were chosen, I was happy with my selection because they all show the parts as having a high polish brushed metal kind of finish, the kind i like. i am not a fan of weathered finish.

So, when i opened up the package, I noticed that all the parts were satin finished, the kind that i absolutely hated. To say that I was truly disappointed would be an understatement. After waiting for 8 long months, what I received was not what was shown in the saber builder. Now I am considering either to re-finish it or just to sell it off. The design of the parts are beautiful but the finishing is absolutely disappointing and the saber builder is downright misleading.

See the finishing in the saber builder and see the difference in the actual product.

Another thing that surprised me is how heavy the parts are. The juggernaught itself weighs 850g (without the blade, sorry I only have a metric scale). In comparison the venom is 440g and the reborn is 420g. That things weighs as much as 2 hilts combined.

Would i buy another ASP? Yes, but I have to make absolutely certain that i avoid those with satin finish. Can the saber builder be trusted to show the actual parts? No.

Can anyone give some suggestions how to turn the satin finished to a polished finish or brushed metal finish?

Update @ May 30.

I apologize for not visiting this thread after my initial post. Truth is i came back several times looking for this post after i posted it and it didn't appear. I concluded that my post wasn't approved due to the issue which wasn't flattering to SF. Then, a post appeared in FB today and i got a reply that my post was actually approved which made me come back and looked and i am pretty surprised there are some good discussions going on here.

I also apologize for the missing pictures. I have now uploaded it to photobucket and made a link here. i hope it will show.

Since my last post, I have made some minor upgrades like polishing the sides of the blades, adding a red button to where it was supposed to be, added some black O rings and accents.

I would have done the mods earlier except that 2 parties indicated their interest in acquiring my hilt but they drag the time and they eventually fizzled out. So now i think i will keep it and slowly customize it to my liking when i have some spare time. I expect it to be an evolution, rather than a revolution.